608.9

Machinery rooms shall be provided with a refrigerant detector with an audible and visual alarm. Where ammonia used as the refrigerant, detection shall comply with IIAR 2. For refrigerants other than ammonia, refrigerant detection shall comply with Section 608.9.1.

608.9.1 Refrigerants other than ammonia.

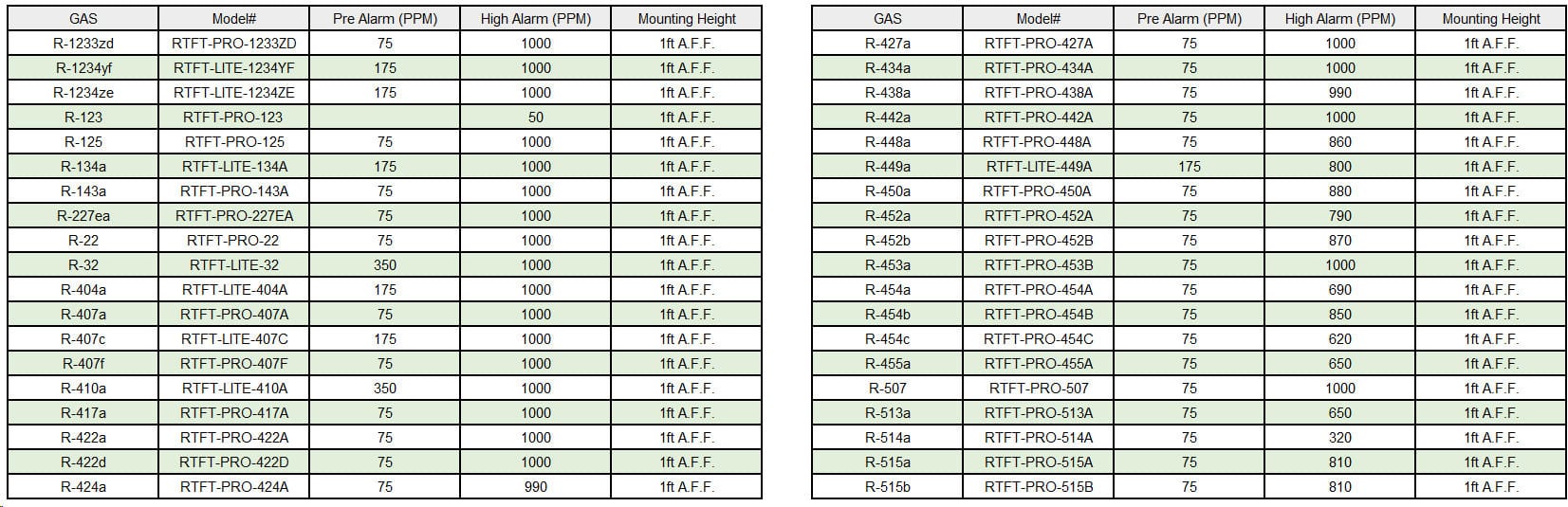

A detector, or a sampling tube that draws air to a detector, shall be provided at an approved location where refrigerant from a leak is expected to accumulate. The system shall be designed to initiate audible and visible alarms inside of and outside each entrance to the refrigerating machinery room and transmit a signal to an approved location where the concentration of refrigerant detected exceeds the lesser of the following:

1) The corresponding TLV-TWA values shown in the International Mechanical Code for the refrigerant classification.

2) Twenty-give percent of the lower flammable limit (LFL)

Detection of a refrigerant concentration exceeding the upper detection limit or 25 percent of the lower flammable limit (LFL), which is lower, shall stop refrigerant equipment in the machinery room in accordance with Section 608.10.1.

608.9

Machinery rooms shall be provided with a refrigerant detector with an audible and visual alarm. Where ammonia used as the refrigerant, detection shall comply with IIAR 2. For refrigerants other than ammonia, refrigerant detection shall comply with Section 608.9.1.

608.9.1 Refrigerants other than ammonia.

A detector, or a sampling tube that draws air to a detector, shall be provided at an approved location where refrigerant from a leak is expected to accumulate. The system shall be designed to initiate audible and visible alarms inside of and outside each entrance to the refrigerating machinery room and transmit a signal to an approved location where the concentration of refrigerant detected exceeds the lesser of the following:

608.10.1 Refrigeration system emergency shutoff.

A clearly identified switch of the break-glass type or with an approved tamper-resistant cover shall provide off-only control of refrigerant compressors, refrigerant pumps and normally closed automatic refrigerant valves located in the machinery room. Additionally, this equipment shall be automatically shut off when the refrigerant vapor concentration in the machinery room exceeds the vapor detector’s upper detection limit or 25 percent of the LEL, whichever is lower.

608.10.2 Ventilation System

A clearly identified switch of the break-glass type or with an approved tamper-resistant cover shall provide on-only control of the machinery room ventilation fans.