In the bustling environment of commercial kitchens, safety is paramount. With hundreds of thousands of these kitchens operating across the United States, ensuring that gas safety is meticulously maintained is crucial to prevent catastrophic accidents. However, many commercial kitchens are inadequately equipped, relying solely on a manual ball valve and a fire suppression system that automatically shuts off the gas when a fire is detected. This minimalistic approach leaves a significant gap in safety protocols, risking lives and property.

The Current State of Commercial Kitchen Gas Safety

It’s estimated that there are over 660,000 food service establishments in the U.S., including restaurants, cafeterias, and institutional kitchens. While these kitchens are equipped with various safety measures, gas safety often does not receive the attention it warrants. Most kitchens have basic safety mechanisms like a manual ball valve for gas shutoff and a fire suppression system designed to cut off the gas supply if a fire is detected. However, these measures alone are insufficient for comprehensive safety.

Limitations of Existing Safety Measures

- Manual Ball Valves: While manual ball valves are a necessary component of gas safety, they require human intervention to operate. In the chaos of an emergency, staff may not have the time or presence of mind to manually shut off the gas supply, allowing a hazardous situation to escalate.

- Fire Suppression Systems: These systems are critical in fire emergencies, automatically cutting off the gas supply when flames are detected. However, they do not address gas leaks or the buildup of dangerous gases like carbon monoxide (CO) and natural gas (NG) before a fire starts.

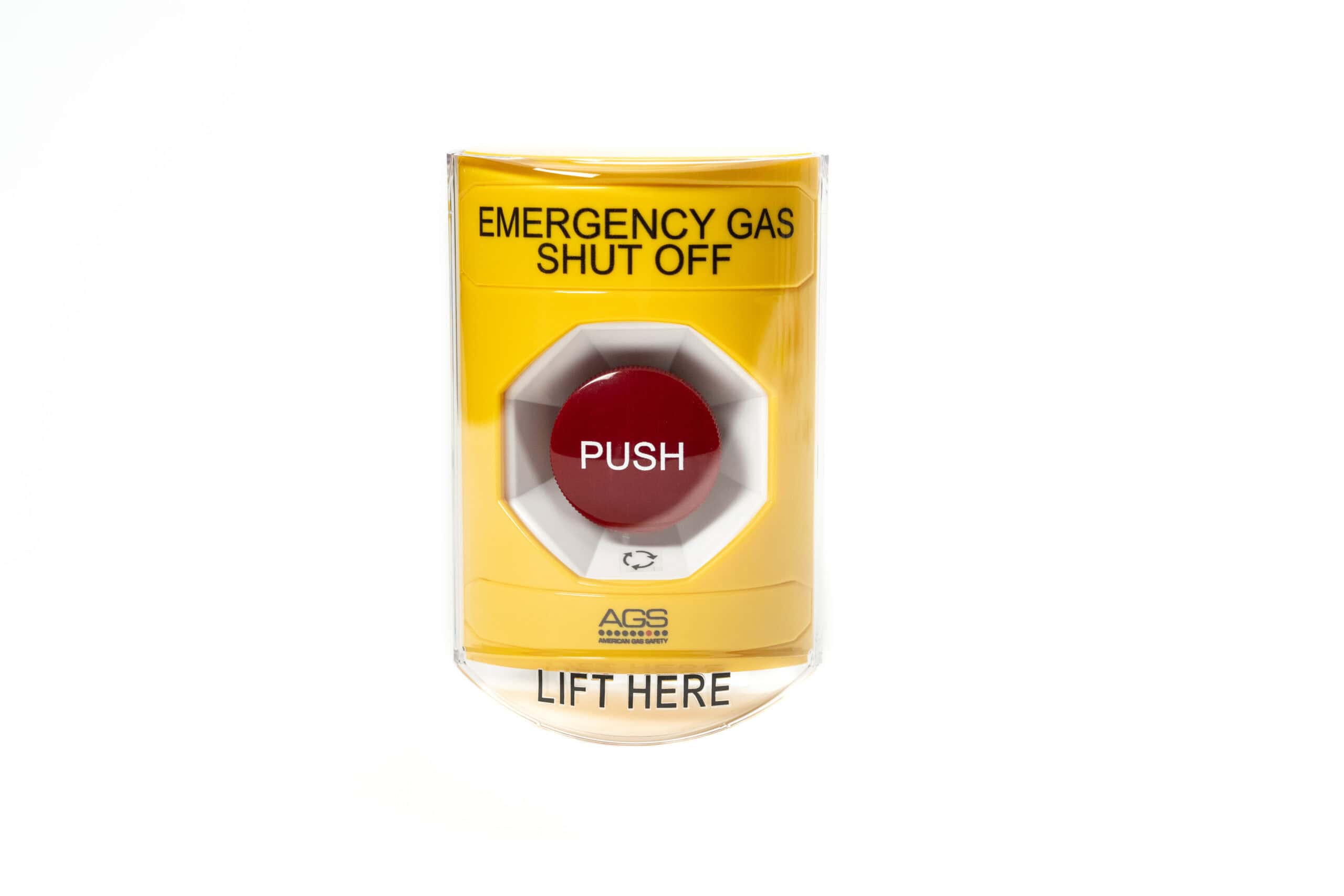

Taking the First Step: Accessible Emergency Button & Valve

Improving gas safety in commercial kitchens starts with the installation of an accessible emergency button and valve. This setup allows kitchen staff to quickly and easily shut off the gas supply in the event of an emergency. However, this should not be the only line of defense. View the range here.

Advanced Safety with the Mini Merlin CO/NG Interlock

To significantly enhance gas safety, commercial kitchens should consider integrating advanced systems like the Mini Merlin CO/NG interlock. This device is designed to shut down the gas supply if dangerous levels of CO or NG are detected, providing an additional layer of protection against gas-related incidents.

Benefits of the Mini Merlin CO/NG Interlock:

- Automatic Gas Shutoff: The Mini Merlin interlock continuously monitors CO and NG levels in the kitchen. If either gas reaches alarm levels, the system automatically shuts down the gas supply, preventing potential explosions or poisoning incidents.

- Real-Time Monitoring: With constant monitoring, the Mini Merlin ensures that gas levels remain within safe limits, providing peace of mind to kitchen staff and management.

- Early Detection and Prevention: By detecting gas leaks and buildup before they reach dangerous levels, the Mini Merlin can prevent emergencies from occurring in the first place, rather than merely reacting to them.

With the sheer number of commercial kitchens in the U.S., enhancing gas safety protocols is not just advisable—it’s essential. While manual ball valves and fire suppression systems provide a basic level of protection, integrating advanced systems like the Mini Merlin CO/NG interlock can significantly reduce the risk of gas-related incidents. By taking these proactive steps, commercial kitchens can ensure a safer environment for staff and patrons alike.

For more information on the Mini Merlin CO/NG interlock and how it can improve gas safety in your commercial kitchen, visit American Gas Safety.