Refrigerant gas is a critical component of HVAC systems, providing efficient cooling in various applications. However, the leakage of refrigerant gases poses significant safety risks, including health hazards and environmental damage. To mitigate these risks, the installation of refrigerant gas detection systems is essential. In this blog post, we’ll explore the best practices and code requirements for refrigerant gas detection, emphasizing the importance of safety in HVAC systems.

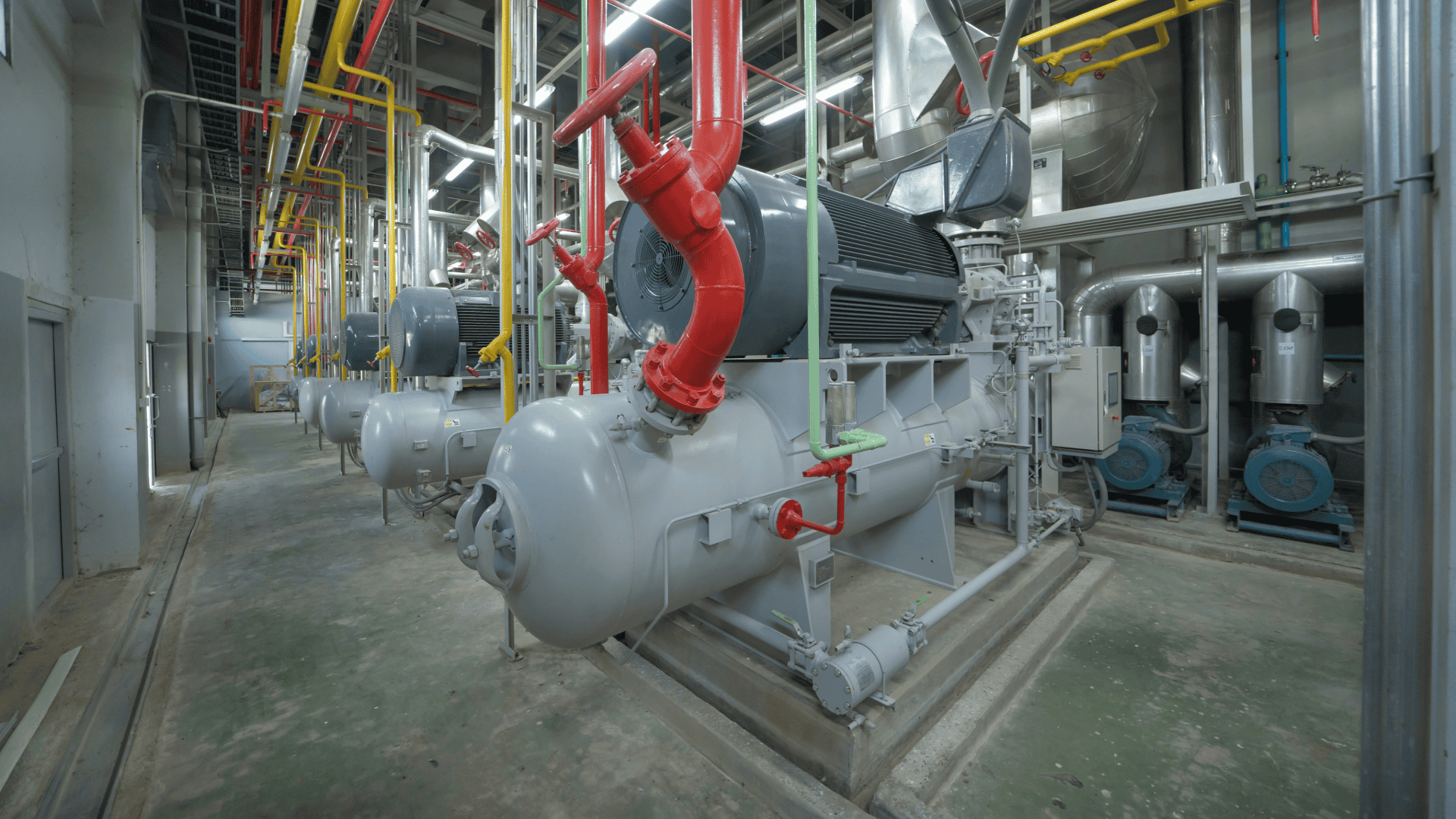

Refrigerant gas detection is typically required in areas where refrigeration or air conditioning systems are present. This includes commercial buildings, industrial facilities, laboratories, and refrigeration plants. These systems often use large quantities of refrigerants, making it crucial to detect any leaks promptly. Common locations for refrigerant gas detection include chiller rooms, mechanical rooms, equipment enclosures, and storage areas.

Best Practice Considerations: When designing and installing refrigerant gas detection systems, several best practices should be followed:

- Proper Placement: Sensors should be strategically located near potential leak sources, such as equipment connections, valves, and piping.

- Regular Maintenance: Routine inspection and calibration of gas detection equipment are essential to ensure accurate and reliable performance.

- Alarm Notification: Gas detection systems should be equipped with audible and visual alarms to alert personnel in the event of a leak.

- Integration with Building Management Systems: Integrating gas detection systems with building automation systems allows for centralized monitoring and control.

- Training and Education: Personnel should be trained on how to respond to gas detection alarms and follow established safety procedures.

Several codes and standards govern the installation and operation of refrigerant gas detection systems. Two notable codes include:

- ASHRAE 15: The ASHRAE Standard 15 establishes safety requirements for refrigeration systems and their components, including refrigerant gas detection.

- International Fire Code (IFC): The IFC outlines requirements for the storage, handling, and use of hazardous materials, including refrigerants.

For further information on these code requirements, click here.

American Gas Safety offers the MerlinGuard refrigerant gas detection range, designed to meet the stringent safety requirements of modern HVAC systems. The MerlinGuard system utilizes advanced sensors and detection technology to provide reliable monitoring of refrigerant gas levels. With options for chiller rooms, VRF systems, and other applications, the MerlinGuard range offers comprehensive protection against refrigerant leaks and is available with over 40 refrigerant gases, including all new lower GWP gases.

Refrigerant gas detection plays a vital role in ensuring the safety and integrity of HVAC systems. By following best practices and adhering to relevant code requirements, building owners and facility managers can mitigate the risks associated with refrigerant leaks. With the AGS MerlinGuard refrigerant gas detection range, businesses can achieve peace of mind knowing that their HVAC systems are effectively monitored for safety hazards.

Click here to view the MerlinGuard refrigerant gas detection range or alternatively contact your local representative.