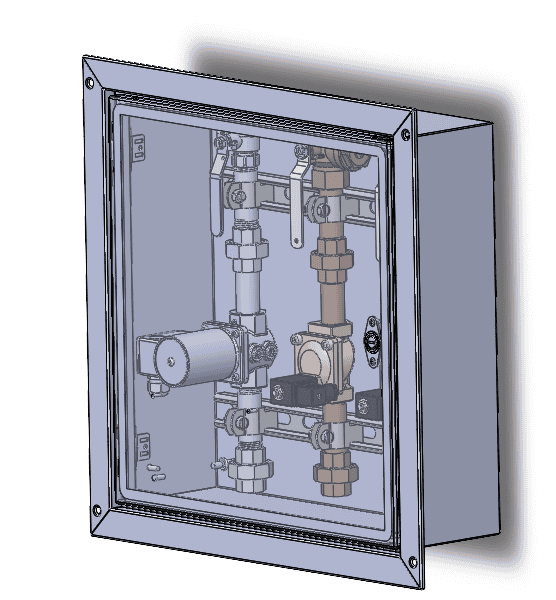

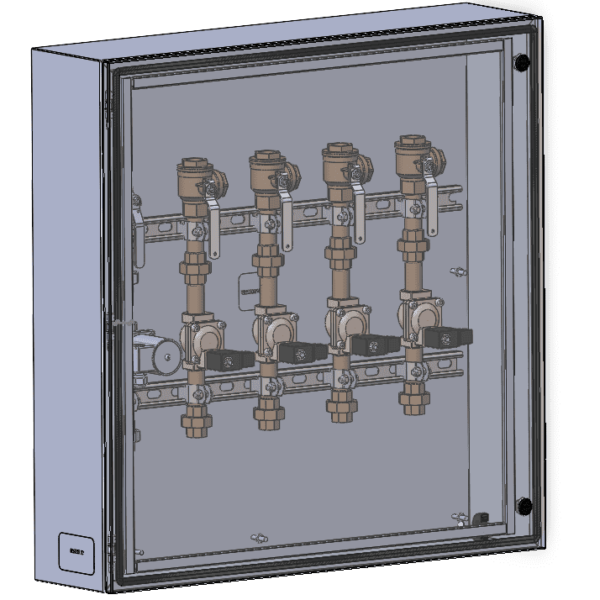

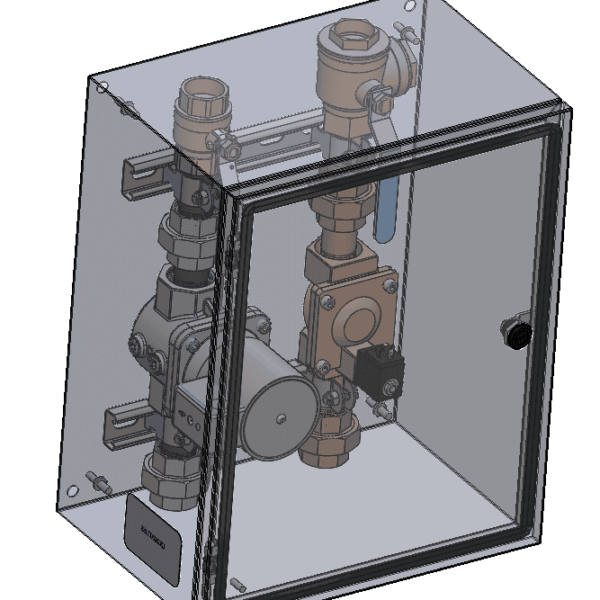

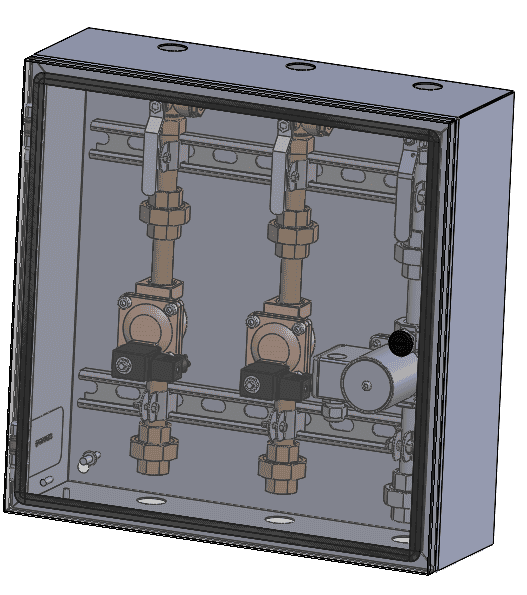

Gas solenoid valves play a crucial role in controlling the flow of gas in various industrial and commercial applications. To ensure their optimal performance and longevity, these valves are often placed on a rack that is housed in enclosures. These racks consist of pre-assembled isolation valves, air and liquid tight grommets, and solenoid valves that are then secured onto a strut in the enclosure. Now, while enclosures offer several advantages, they also come with certain drawbacks.

One of the main benefits of using enclosures for gas solenoid valves is the accessibility in the need of servicing. If in-room accessibility is not a concern, they could be placed in the ceiling space, if the room has an accessible drop ceiling. Now, what is accessible defined as? Per NFPA 54, “accessible” refers to being capable of being reached quickly for operation, repair, or inspection without requiring those to whom ready access is requisite to climb over or remove obstacles or to resort to portable ladders, chairs, etc. This means that the item in question can be accessed without difficulty or the need for specialized tools or equipment.

An enclosure can also provide protection from environmental factors. Enclosures shield the valves from dust, dirt, and other airborne particles that could clog or damage them, ensuring smooth operation. They also provide a barrier against moisture, which can cause corrosion and lead to malfunction. Additionally, enclosures help maintain a stable temperature around the valves, protecting them from extreme heat or cold that could affect their performance.

Safety is another significant advantage. Enclosures can prevent sparks from interacting with flammable gases in hazardous environments, reducing the risk of explosions. They also protect personnel from accidental contact with the valves, which may operate at high temperatures or pressures. By shielding the valves from harsh environmental conditions and physical damage, enclosures can extend the lifespan of gas solenoid valves, reducing maintenance costs and downtime.

Furthermore, racks and enclosures can be used to reduce installation time on the field. By having them prefabricated, the plumber will save time, thus cost, and the enclosures will be factory-tested to ensure guaranteed performance.

However, there are several disadvantages to using enclosures for gas solenoid valves. Space requirements can be a limitation. Enclosures require additional space, which can be problematic in compact installations or where space is at a premium. Enclosures also come at a cost, given that the contractor does not feel comfortable building these themselves on the field or they want a quicker, easier installation.

In environments such as plenum spaces, enclosures are not recommended due to installation complexity. Here, you may want to consider putting the valves in the wall. However, if the walls are connected to the plenum space, then the best course of action would be to have an enclosure in the wall with a vent to the room for a way to detect a potential gas leak. Plenum spaces often have specific requirements for equipment housing to maintain air quality and prevent the spread of contaminants or fire hazards. Enclosures tailored for these spaces can help meet these regulatory needs effectively.

Finally, enclosures need to be carefully designed to accommodate the specific requirements of the gas solenoid valves and the operational environment, adding complexity to the system design.

The decision to use enclosures for gas solenoid valves involves weighing the benefits of accessibility, protection, safety, and extended lifespan against the drawbacks of space and design requirements. In many cases, the advantages of using enclosures heavily outweigh the disadvantages, particularly in environments where accessibility and safety are paramount. However, it is essential to consider the specific needs and constraints of each application to make an informed decision.

View the AGS range of pre-assembled solenoid valve enclosures here, or alternatively contact your local representative for further information.