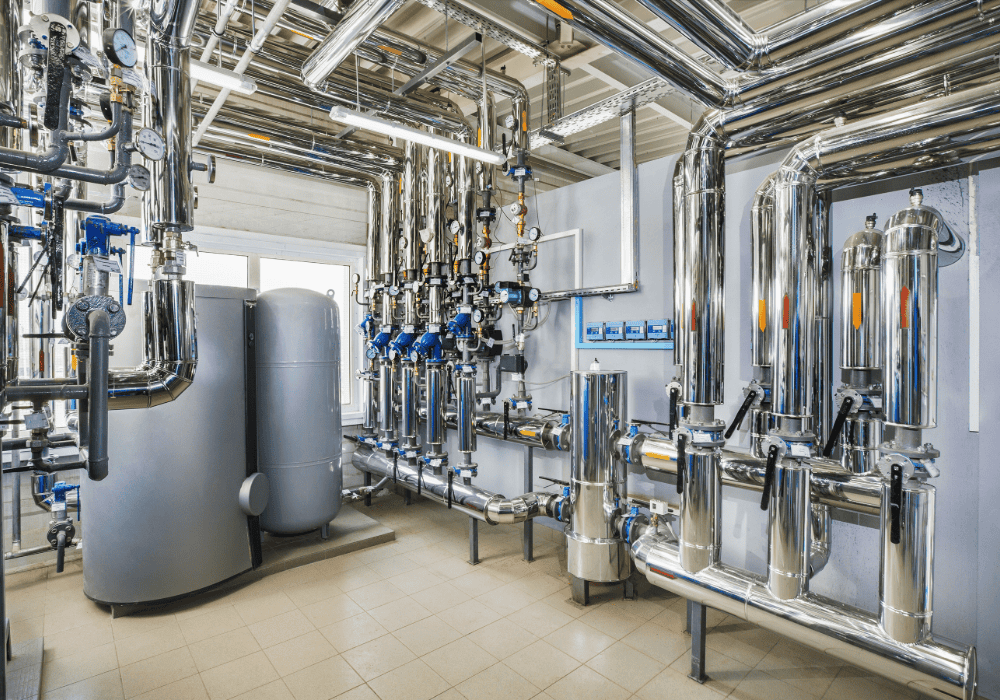

Boiler rooms are vital to the functioning of many industrial and commercial facilities, supplying necessary heat and hot water for everyday operations. However, these confined spaces pose a significant risk due to the potential presence of carbon monoxide (CO). Recognizing the dangers of CO exposure and installing effective detection systems are essential steps in protecting lives and maintaining safe boiler room operations.

Carbon monoxide is a colorless, odorless gas generated by the incomplete combustion of carbon-containing fuels such as natural gas, oil, or wood. Its stealthy nature makes it especially hazardous, as it can build up unnoticed in enclosed spaces like boiler rooms. Exposure to elevated levels of CO can result in carbon monoxide poisoning. Carbon monoxide binds to hemoglobin in the bloodstream, impairing the blood’s capacity to transport oxygen to essential organs and tissues. Even low levels of CO exposure can result in symptoms such as headaches, dizziness, nausea, and fatigue.

The standard measurement for carbon monoxide is parts per million or ppm. To understand how small a ppm is, consider this. One part per million is equal to:

- One day in 2,739 years;

- One interception in 7,692 football games; or

- One kernel of corn in 1,250 ears of corn.

CO is generated when carbon-based fuels are burned in environments with insufficient oxygen supply. In boiler rooms, combustion processes occur continuously to generate heat for heating systems and hot water. If boilers are not properly maintained or vented, incomplete combustion can occur, leading to the production of CO.

Given the silent and potentially deadly nature of CO, having reliable detection systems in boiler rooms is paramount. Installing CO detection and interlock systems in these environments is crucial. These systems are designed to continuously monitor CO levels and initiate emergency shutdown procedures if elevated concentrations are detected. They can also trigger audible and visual alarms when CO concentrations exceed safe thresholds, alerting personnel to potential dangers. By shutting off the fuel supply to combustion equipment, CO emissions are halted, protecting occupants from potential harm.

Contact American Gas Safety or your local representative for further information.