When it comes to maintaining safety and compliance in facilities with boilers and water heaters, understanding the nuances of code requirements is crucial. In this blog, we’ll dive into the specifics of boiler rooms versus mechanical rooms and how Mini Merlin’s CO interlock system plays a key role in ensuring safety. We’ll also explore how code requirements for carbon monoxide (CO) boiler interlocks vary across states like Texas, Georgia, New York, and Florida.

Boiler Rooms vs. Mechanical Rooms: What’s the Difference?

The distinction between a boiler room and a mechanical room is not just about semantics; it’s a significant factor that influences the safety regulations and code requirements applicable to each space. The main difference lies in the size and capacity of the equipment housed in these rooms.

Boiler Room: According to the American Society of Plumbing Engineers (ASPE), a room is classified as a boiler room if it contains a boiler with a maximum capacity of up to 199,999 MBH (Thousand British Thermal Units per Hour). This classification dictates specific safety measures and ventilation requirements to ensure safe operation and prevent hazards such as carbon monoxide buildup.

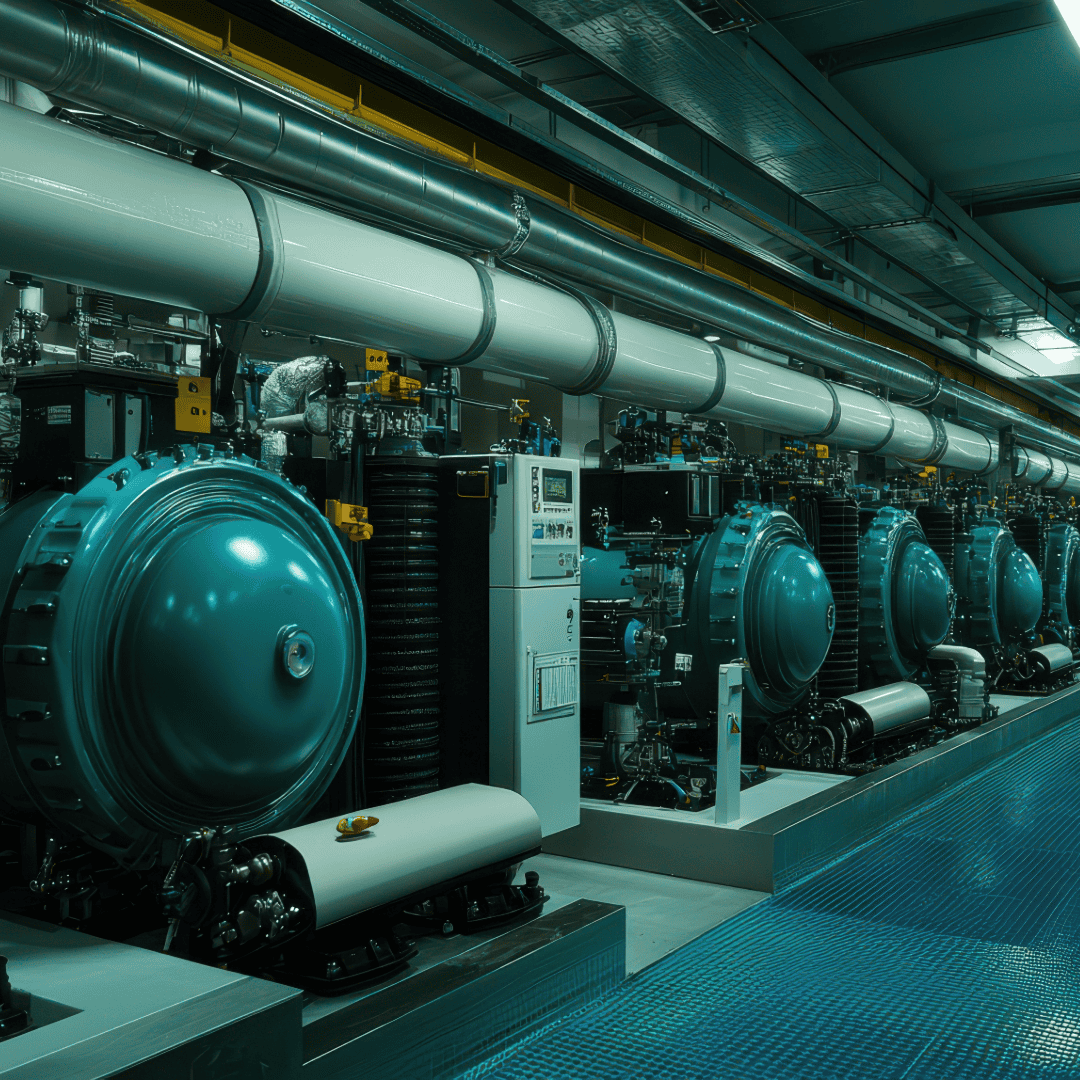

Mechanical Room: If the equipment in the room exceeds 199,999 MBH, the space is considered a mechanical room. Mechanical rooms typically house larger and more complex systems, including high-capacity boilers and water heaters. The code requirements for mechanical rooms are more stringent due to the increased risk associated with the higher capacity of the equipment.

Enhancing Safety in Boiler and Mechanical Rooms

Adding safety features to boiler and mechanical rooms is crucial for protecting occupants and ensuring compliance with regulations. Here are key steps to enhance safety in these environments:

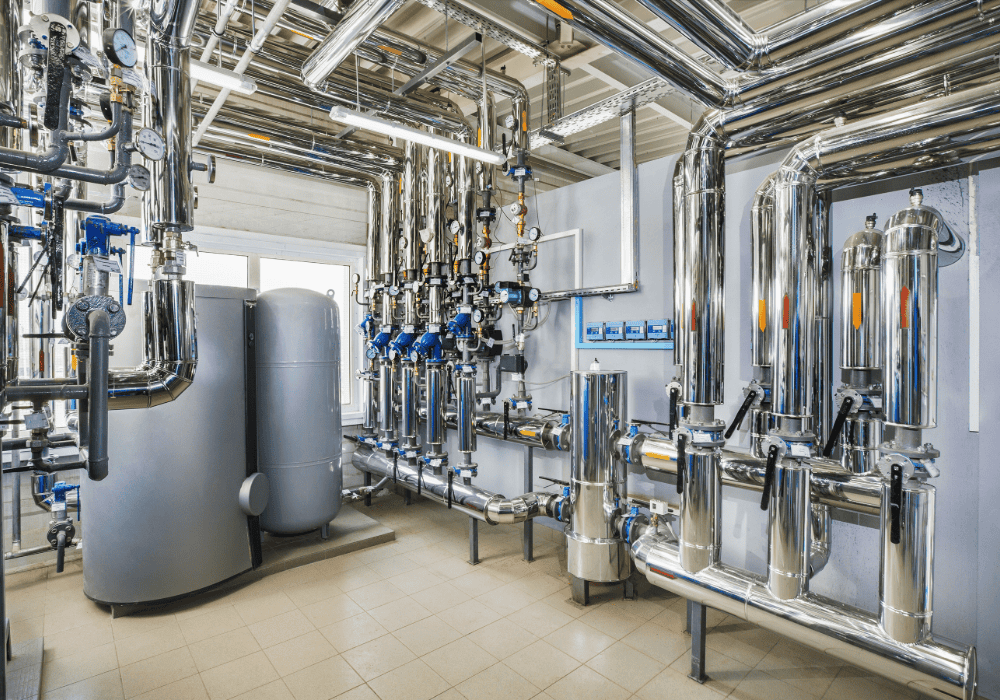

- Proper Ventilation: Ensure that both boiler and mechanical rooms are well-ventilated to prevent the accumulation of hazardous gases. Proper ventilation helps maintain air quality and reduces the risk of CO buildup.

- Regular Maintenance: Conduct regular maintenance and inspections of boilers and associated equipment to identify and address potential issues before they become serious problems. This includes checking for leaks, corrosion, and proper functioning of safety devices.

- Fire Safety Measures: Install and maintain fire detection and suppression systems, such as sprinklers and fire alarms, to protect against fire hazards. Ensure that these systems are regularly tested and maintained.

- Emergency Shut-Off Systems: Implement emergency shut-off systems that can quickly deactivate boilers or other equipment in case of a malfunction or hazardous condition.

- Training and Procedures: Train staff on safety procedures and emergency response protocols. Ensure that everyone is aware of how to operate safety systems and respond to emergencies.

What is a Carbon Monoxide Boiler Interlock?

A carbon monoxide boiler interlock is an essential safety feature that ensures the boiler or gas supply to the boiler is automatically shut down if carbon monoxide (CO) levels reach a predefined alarm threshold. This system is crucial for preventing hazardous CO conditions and is a code requirement in several states. Here’s how it works:

- Detection: The interlock system includes a CO sensor that continuously monitors the air for carbon monoxide levels.

- Alarm and Shutdown: If CO levels exceed a specified threshold—often set at 50 parts per million (ppm)—the system triggers an alarm and automatically shuts down the boiler or cuts off the gas supply. This immediate response helps prevent dangerous conditions and protects occupants.

- Compliance: In states where carbon monoxide boiler interlocks are required, installing and maintaining this system is a legal obligation, ensuring that facilities are equipped to handle CO risks effectively.

Code Requirements for Carbon Monoxide Boiler Interlocks by State

Compliance with state-specific regulations for carbon monoxide boiler interlocks is essential for maintaining safety and meeting legal requirements. Here’s a summary of the code requirements in Texas, Georgia, New York, and Florida:

Texas

Under the Texas Administrative Code (TAC) Chapter 65, boiler rooms with carbon monoxide-producing equipment must be equipped with CO detectors that include a manual reset. Key requirements include:

- Alarm Threshold: CO detectors must trigger an alarm and shut down the boiler if CO levels exceed 50 ppm.

- Shutdown: The system must automatically disable the burners upon detecting high CO levels or a loss of power.

- Calibration: CO detectors must be calibrated according to the manufacturer’s recommendations or every eighteen months, with records posted at or near the boiler.

Georgia

The 2022 Rules & Regulations of the State of Georgia – Rule 120-3-26-.07 stipulates that:

- Alarm Threshold: CO detectors must alarm at 50 ppm and shut down the burner if CO levels exceed 200 ppm.

- Manual Reset: The detectors must have a manual reset function.

- Calibration: Detectors should be calibrated every eighteen months or as recommended by the manufacturer, and records must be accessible.

- Power Loss: The system must disable burners if the detector loses power.

New York

According to Chapter 908-01 of the New York City Building Code, carbon monoxide detectors must be installed in rooms with CO-producing equipment. Key requirements include:

- Alarm Activation: Detectors must shut down the CO-producing equipment when activated.

- Installation: Detectors must be installed according to NFPA 720 and local regulations.

- Detection Zones: CO detectors should be placed in central locations and additional spots to ensure full coverage within detection zones.

Florida

Rule Chapter 69A-70 requires:

- CO Sensors: Boiler rooms in public lodging establishments with sleeping rooms must have CO sensors that comply with Underwriters Laboratories Standard 2034 or equivalent.

- Alarm Threshold: CO detectors must shut off the boiler at 35 ppm and include a manual reset function.

- Integration: The CO sensors should be integrated with the facility’s fire detection system.

Understanding the distinction between boiler rooms and mechanical rooms, along with their specific code requirements, is vital for ensuring compliance and safety. The inclusion of a carbon monoxide boiler interlock system, as mandated in states like Texas, Georgia, New York, and Florida, enhances safety by providing real-time monitoring and automatic control features. By adhering to local code requirements and integrating advanced safety systems like Mini Merlin, facility managers can effectively mitigate risks and ensure a safe operational environment.

For more information on how Mini Merlin can help with code compliance and safety, feel free to reach out to us or consult your local representative.